|

|

|

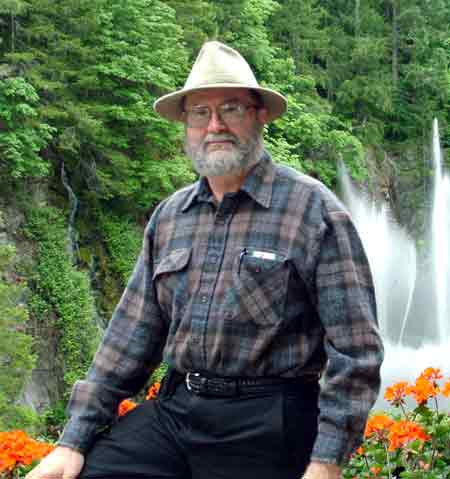

H&R 922, 732 Rnd Stag (21c)

|

| |

|

Quantity in Basket:

None

Code: HR_21C

Price: $75.00

Shipping Weight: 0.15 pounds

|

| |

This is a staghorn pattern grip set for the round butt

small frame versions of the Harrington and Richardson Models

922, 732, and similar. Bear in mind that H&R used the same

model numbers for both larger, square butt revolvers and

the smaller shorter barrel round butt version, and order the

right one for your gun.

In other words, look at your gun, look at the dimensions on

these grips, compare them using a ruler, and if your gun is

obviously not the same shape or size, don't order these. People

do that with some regularity, and that's why I pound away

on the idea that a tracing of your grips surely does

avoid problems of that kind. But so would taking a look

at the numbers, and making a few simple measurements of

your existing grips or gun frame. If your 922 or 732 uses

a "Coke-bottle" shaped pair of grips with a big square

flat base, these are not the right grips for it.

Another thing H&R did was mix up the various kinds of

mounting methods without changing the model numbers. If

your gun requires a pair of 6-32 oval head screws to

fasten each separate grip panel onto the gun, with a U-shaped

bracket surrounding the hammer spring, then order the

appropriate 6-32 mounting method. If your gun has the

hammer spring located so it won't interfere with a single

screw run all the way through the grip frame, then you

can use the standard No.4 single screw mounting kit. If

you do not have the 6-32 tapped U-shape bracket inside

the gun frame (a separate, loose piece that straddles the

hammer spring) then probably you'll need to get or have

one made unless the existing grips fasten with a single

screw. I mention this because sometimes folks get a gun

that has no grips, and no mounting bracket, and they

don't know what to use. Look at the standard hole

location on the chart, and see if that would put the

screw right into the hammer spring, or if a screw at

that point would be able to go past the hammer spring.

That tells you which mounting will work for you.

These pictures of a factory grip have the hollowed back and a pin at top and bottom as well as the recessed bracked. The grips I make can

have a recess for the bracket, but I don't try to put a pin in the thin top section. The solid Tombstone grip backs are well secured with a pin

at the bottom. Tombstone grips, being cast in open top molds where the back is the surface of the liquid before it cures, cannot have molded-in plastic pins. Instead, metal pins are inserted, which are stronger.

These pictures of a factory grip have the hollowed back and a pin at top and bottom as well as the recessed bracked. The grips I make can

have a recess for the bracket, but I don't try to put a pin in the thin top section. The solid Tombstone grip backs are well secured with a pin

at the bottom. Tombstone grips, being cast in open top molds where the back is the surface of the liquid before it cures, cannot have molded-in plastic pins. Instead, metal pins are inserted, which are stronger.

I don't have the U-shape brackets but I understand that

Numrich Arms and certain other parts dealers can supply

them. It would not be too hard to fabricate one with 12 to

14 gauge sheet metal, a small vise, tap hammer, and a 6-32 drill and tap.

Here are the dimensions of this grip:

- Width across the flat base = 1.1 inches

- Height to the screw hole = 1.1 inches

- Width across grip at the screw hole center = 1.1 inches

- Front edge to center of screw hole = 0.5 inches

- Width across the top "ears" = 0.9 inches

- Height of the round top above line connecting the "ears" = 0.3 inches

- Overall height of grip = 2.3 inches

- Front ear height 90-degrees to base = 1.7 inches

- Rear ear height 90-degrees to base = 2.2 inches

|

Related Item(s)

|

Code

|

Name

|

Price

|

Availability

|

|

|

HR_23a

|

H&R Mod.732 (23a)

|

$68.00

|

|

|

HR_28a

|

H&R 922, 732 Rnd Butt (28a)

|

$68.00

|

|

|

HR_110c

|

H&R 733, 732, NEF 733 (110c)

|

$68.00

|

|

|

HR_141f

|

H&R 929, 622, 732 Stag (141F)

|

$75.00

|

|

|

HR_11F

|

H&R 922, 732, 929 Ext Round Butt (11F)

|

$68.00

|

|

|

HR_21D

|

H&R 922, 732 Round Smooth (21D)

|

$68.00

|

|

|

These pictures of a factory grip have the hollowed back and a pin at top and bottom as well as the recessed bracked. The grips I make can have a recess for the bracket, but I don't try to put a pin in the thin top section. The solid Tombstone grip backs are well secured with a pin at the bottom. Tombstone grips, being cast in open top molds where the back is the surface of the liquid before it cures, cannot have molded-in plastic pins. Instead, metal pins are inserted, which are stronger.